Colour Methods for Metal Lapel Pins

Emblem badge coloring

Cloisonné (Hard Enamel) Lapel Pins V.S. Imitation (Soft) Hard Enamel Lapel Pins

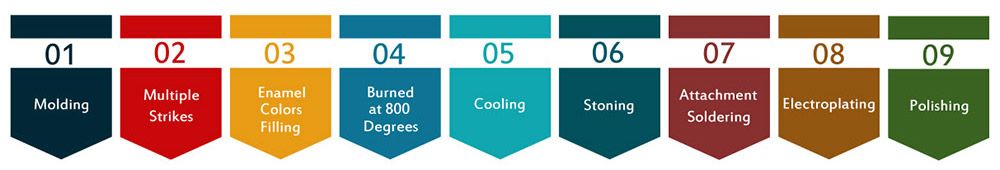

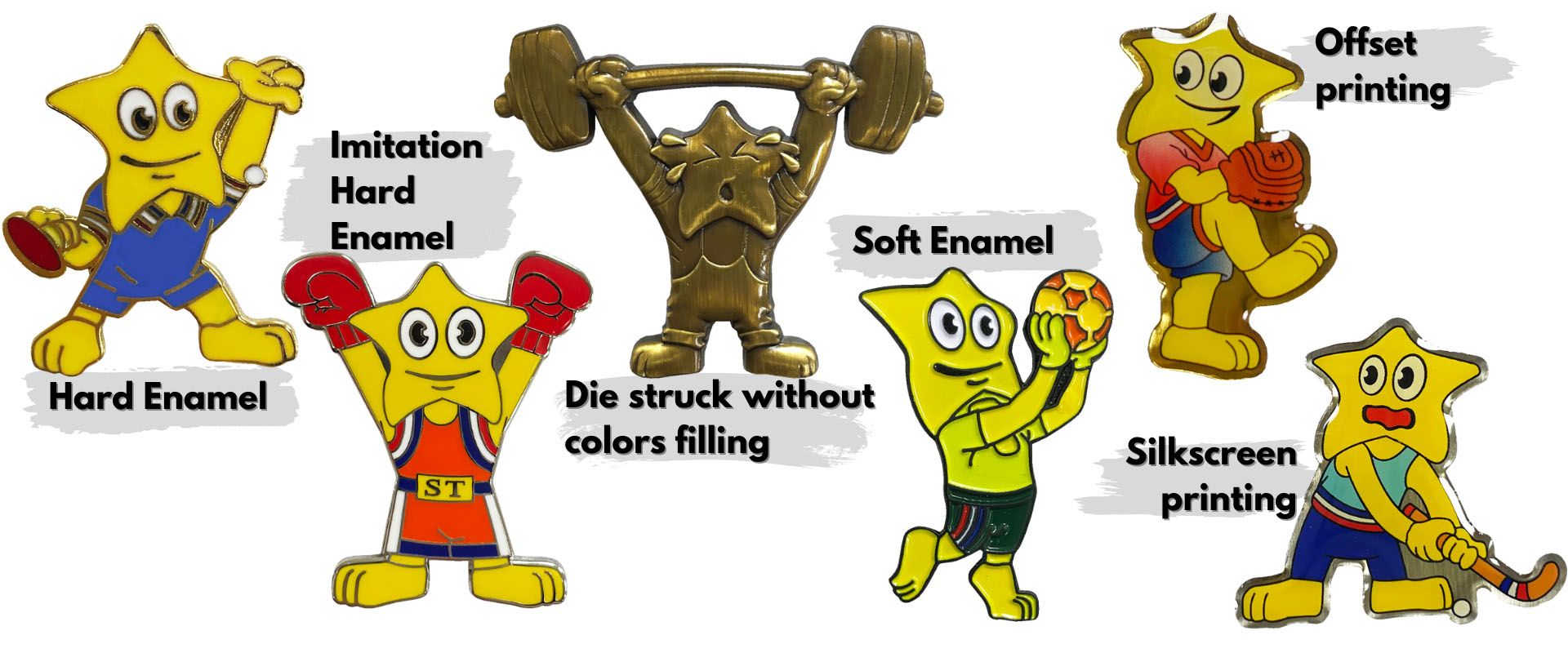

Cloisonné Lapel Pins, often regarded as the highest quality lapel pins, are also known as hard enamel pins. These pins are typically crafted from high-grade copper. The cloisonné process involves applying enamel powder or mineral ore, which is then fired at over 800°C to harden and cure the enamel. This technique results in a durable finish that can last for many years, making traditional cloisonné lapel pins a symbol of achievement and a preferred choice for various organizations. The polished surface is exceptionally smooth, with no detectable metal ridges when you run your finger across the pin. In contrast, Imitation Hard Enamel Lapel Pins (also known as soft enamel pins) have largely replaced traditional cloisonné due to their similar appearance, more affordable cost, and wider range of available colors, including PMS Pantone colors. While imitation hard enamel pins offer a comparable look, they are more cost-effective, making them a popular choice for organizations looking to balance quality with budget.

Soft Enamel Pins

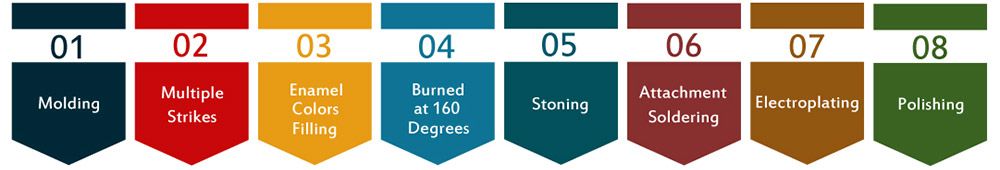

Soft enamel pins are the most popular pin types and offer great appearance at an affordable price, especially appropriate used for corporate pins and team trading pins. Colors are stored in syringes and applied by injection in the recessed areas and then bake the enamel hard. The enamel clings to the edges and recessed below the metal die line (that stops the enamels from mixing), meaning the paint is at a lower level than the metal borders surrounding. If you rub your finger over a soft enamel pin you will feel the raised metal lines. We also can add epoxy coating onto soft enamel to protect the enamel and make the enamel smooth and flat.

Two-Tone Die Struck Lapel Pins

One of the features of die struck pins is classic and produce only with a simple metal (without colors filling). Die struck lapel pins are made with a sheet of raw metal. Then, the mold is produced depending on your design and struck under extreme pressure. Multiple strikes are necessary required to ensure your design into the metal. Once the pin design is shaped onto the raw metal, the strip will be cut perfectly and separated into smaller strips. As the final procedure has been finished, it can be worked in many ways: plating, polishing or antiquing.

Printing Lapel Pins

The two primary methods for creating printed lapel pins are Offset Printing and Silkscreen Printing. Offset printing pin is ideal for capturing detailed images and gradients, while silkscreen printing pin excels in producing solid, vibrant colors with precise accuracy. Both techniques allow for intricate designs that wouldn’t be possible with traditional enamel pins, making printing lapel pins an excellent choice for complex logos or artwork.

Metal Lapel Pin Case Study: A Closer Look at Cloisonné, Soft Enamel, and Printed Styles

This collection showcases various lapel pin styles in different colors. Cloisonné Lapel Pins and Imitation Hard Enamel Lapel Pins feature a smooth, polished surface, while Soft Enamel Pins have a textured finish, giving them a more pronounced dimensional effect with visible shadows. For Soft Enamel Pins without color, the exposed metal surface is more prominent, often enhanced with antique plating for a richer, more layered appearance.

Offset Printing Lapel Pins allow for gradient color printing, making them ideal for intricate designs, while Silkscreen Printing Lapel Pins use CMYK color for precise color reproduction. In most cases, Printing Lapel Pins are finished with an epoxy coating for added protection and a glossy finish.

- VideoTest ReportRelated Products

This video provides a detailed overview of different types of lapel pins, helping you choose the best style for your logo or design. It covers the characteristics and benefits of various pin badge types, such as Cloisonné, Soft Enamel, and Printed Lapel Pins, offering insights into which option is ideal for your needs.

This video provides an in-depth explanation of the differences between Soft Enamel and Imitation Hard Enamel lapel pins. It offers a detailed comparison to help you understand which type is better suited for your specific needs. Please refer to the video for more information.