Understanding 2D and 3D PVC: Which is Right for Your Custom Needs?

How Do 2D and 3D PVC Products Compare?

At Star Lapel Pin, we are a trusted supplier specializing in the professional production of high-quality PVC products, including lapel pins, custom keychains, bottle openers, medals, PVC magnets, and more. With years of expertise, we craft items tailored to your unique needs, offering both 2D and 3D designs to bring your ideas to life. A common question we get is: what’s the difference between 2D and 3D PVC products? The answer lies primarily in their design, structure, and visual appearance, which stem from how they are manufactured and intended to be used. Here’s a breakdown:

2D PVC Products

● Definition: 2D PVC products are flat or have a single-plane design. They feature a two-dimensional appearance with only length and width, lacking significant depth.

● Appearance: They typically have a raised or embossed design on a flat surface, giving a slight illusion of depth, but they don’t extend outward in a fully three-dimensional way. Think of a logo or text that’s slightly elevated but still essentially flat.

● Manufacturing: These are often made by layering PVC material (sometimes with ink or color) onto a base, using molds that create a raised effect without complex contours. Techniques like screen printing or simple molding are common.

● Examples: Custom keychains with a flat logo, lapel pins with raised designs, magnets featuring a simple emblem, or a PVC patch with embossed text or graphics.

● Advantages:

Simpler and cheaper to produce.

Lightweight and easier to attach to surfaces (e.g., clothing or bags), like a PVC patch on a jacket.

Ideal for minimalist or budget-friendly designs, such as lapel pins for events.

3D PVC Products

● Definition: 3D PVC products are fully three-dimensional, incorporating length, width, and depth.

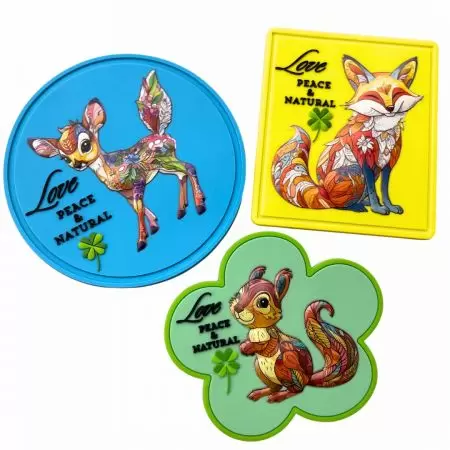

● Appearance: These products have a more realistic, tactile, and dynamic look. They can feature intricate details, undercuts, and varying heights, resembling small figurines or objects with depth on all sides.

● Manufacturing: Created using more advanced molding techniques, such as injection molding or multi-layer casting, where liquid PVC is poured into detailed 3D molds. This allows for complex shapes and textures.

● Examples: Custom keychains shaped like a miniature car, bottle openers with a sculpted handle, magnets resembling a tiny animal, or a PVC patch with pronounced, detailed contours.

● Advantages:

More visually appealing and realistic due to depth and detail, perfect for standout lapel pins.

Better suited for intricate or artistic designs, like a 3D bottle opener.

Offers a premium, high-quality feel for items like custom keychains.

Practical Example

A 2D PVC product might be a PVC patch with a raised logo for a jacket or a lapel pin with a flat emblem.

A 3D PVC product could be a custom keychain shaped like a spaceship or a bottle opener with a sculpted grip.

In essence, 2D PVC is about simplicity and affordability (great for magnets or lapel pins), while 3D PVC is about depth, detail, and a premium look (ideal for custom keychains or bottle openers). Which one to choose depends on the purpose, budget, and desired aesthetic!

- VideoTest ReportRelated Products