Cutout Design Coin | Embroidered patches manufacturer | Star Lapel Pin

If your design includes open spaces, intricate details, or complex shapes, our zinc alloy die-cast coins are the perfect solution for your design coin needs. The exceptional ductility of zinc alloy makes it ideal for die casting, allowing us to achieve unmatched precision across a diverse array of coin and medal styles. The cut-out process can be applied to both the outer and inner sections of the coin. Additionally, this cut-out feature can transform your challenge coin into a functional bottle opener, if desired. Star Lapel Pin is high-quality Cutout Design Coin, Making Challenge Coins with Die Cast Zinc Alloy manufacturer from Taiwan since 1984. Star Lapel Pin is a trusted and awarded custom Cutout Design Coin manufacturer meeting European standard EN71 and low lead standards in the United States. Their advanced technology, combined with a dedicated team of professionals, ensures that customer demands are consistently met. Star Lapel Pin's expansive manufacturing site spans over 64,000 square meters and employs 1000 skilled workers, emphasizing timely delivery and customer satisfaction.

Cutout Design Coin

Making Challenge Coins with Die Cast Zinc Alloy

If your design includes open spaces, intricate details, or complex shapes, our zinc alloy die-cast coins are the perfect solution for your design coin needs. The exceptional ductility of zinc alloy makes it ideal for die casting, allowing us to achieve unmatched precision across a diverse array of coin and medal styles. The cut-out process can be applied to both the outer and inner sections of the coin. Additionally, this cut-out feature can transform your challenge coin into a functional bottle opener, if desired.

What is a Die Casting Coin?

A die casting coin is a meticulously crafted piece of artistry, created through a specialized metal casting process that ensures precision, durability, and intricate design. Unlike traditional coin-making methods, die casting is particularly suited for producing 3D custom coins with highly detailed surfaces and complex shapes. This process results in challenge coins that are not only visually striking but also robust, making them ideal for commemorative and recognition purposes.

The journey of creating a die casting coin begins with the creation of a mold. This die is expertly designed to capture every detail of the custom coin's intended design. Once the die is prepared, molten metal—typically zinc, pewter, or other alloys—is injected under high pressure into the die cavity. This crucial step ensures that the metal fills every intricate detail of the mold, capturing even the finest features of the design with clarity and precision. As the molten metal cools and solidifies, the raw form of the custom coin takes shape. After the cooling process, the coin is carefully removed from the mold. Any excess metal is then trimmed away, leaving behind a finely detailed, sturdy coin. The custom coin is now ready for additional finishing steps, such as polishing, coloring, and engraving, to further enhance its visual appeal.

Ideal Applications for Die Casting Coins

Die casting is especially popular for producing challenge coins, commemorative medallions, and recognition pins. These personalized coins are often used to honor military personnel, first responders, and corporate achievements. Their detailed design and high-quality finish make them a cherished keepsake for those who receive them.

A die casting coin is a masterpiece of craftsmanship, offering a combination of precision, durability, and design flexibility. Whether you're creating coins for a commemorative event, a special recognition, or to honor a specific group or achievement, the die casting process ensures your personalized coins will be detailed, durable, and meaningful. With the option to create 3D designs and intricate features, die cast challenge coins stand as timeless symbols of achievement and honor.

Complimentary Artwork Review and Approval Service

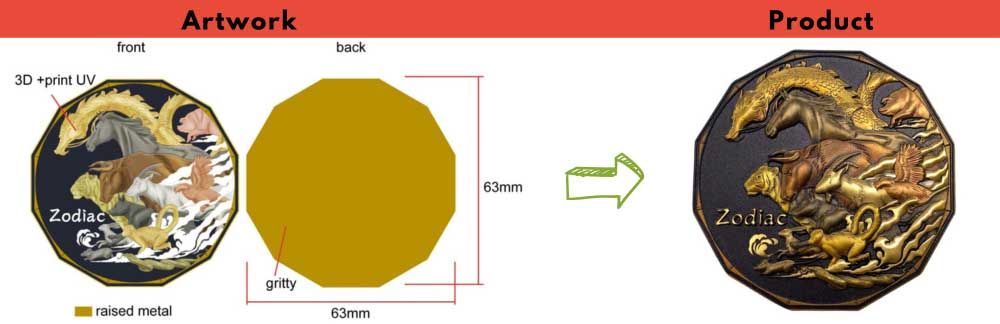

We offer free artwork service for your review and approval before production. Simply submit your design in vector formats, such as ai or eps, and our in-house designer will make an artwork based on your design. Artworks are typically done within one working day, and we welcome discussions for any questions about your unique challenge coin design.

Specification

- Material: Zinc alloy, Pewter, Tin

- Process: Hard enamel, Imitation hard enamel, soft enamel, stamped or molded without coloring.

- Plating Process: Gold, Silver, Bronze, Nickel, Copper, Rhodium, Chrome, Black nickel, Dyeing black, Antique Gold, Antique Silver, Antique Copper, Satin Gold, Satin silver, dye colors, dual plating color

- Size: Custom made. According to customer's requirements.

- Shape: Custom made. According to customer's requirements.

Order Information

- MOQ: 100 PCS

- Package: OPP Bag

- Payment: T/T / PayPal / Credit Card

- Delivery: Need to confirm again when customer approved the artwork / samples.

- Lead Time: 15-20 days. lead time is negotiable.

- VideoRelated ProductsFAQ

Whether you’re creating a commemorative piece, a challenge coin, or a recognition medal, our die casting process guarantees durability, precision, and a premium feel. Learn how we bring your vision to life, one coin at a time.

Injected under high pressure, the zinc alloy cools and solidifies, creating a strong, durable product that retains the fine details and 3D features of the original design.

Cutout Design Coin | Soft PVC Promotional Products manufacturer | Star Lapel Pin

Located in Taiwan since 1984, Star Lapel Pin Co., Ltd. has been a manufacturer of custom promotional products. Their main promotional gifts and souvenirs include, Cutout Design Coin, custom lapel pins and medals, challenge coins, metal souvenirs, personalized leather souvenirs, custom metal promotional products, corporate giveaways and soft PVC and silicone items, which offers high-quality items tailored to B2B buyers globally.

They comply with the European EN71 standard and low lead standards in the U.S. With over 36 years in the metal industry, they have continuously updated their machinery and equipment. Their manufacturing facility covers over 64,000 square meters and employs 1000 experienced workers. They have been providing high quality promotional gifts since 1984 and ensure customer satisfaction with every order.

Star Lapel Pin has been offering customers high-quality promotional gifts since 1984, both with advanced technology and 40 years of experience, Star Lapel Pin ensures each customer's demands are met.

Have any Question?

You are welcome to contact us via email directly:

service@starlapelpin.com