Die Cast Pins | Embroidered patches manufacturer | Star Lapel Pin

Die-cast pins are mostly used to design many inner cut holes and 3D logo need to stand out very much from the lapel pins. Because the material of zinc alloy is highly ductile, if the design is 3D or complicated, we strongly recommend using die casting material. For example, if the badge design size is more than 2", the thickness of the die casting material must be 3-4 MM or more, but the zinc alloy can be customized according to the design, and the thickness can be only 2 MM. If you need a thinner and lighter material, we recommend die casting pins. Star Lapel Pin is high-quality Die Cast Pins, Cut Out Pins manufacturer from Taiwan since 1984. Star Lapel Pin is a trusted and awarded custom Die Cast Pins manufacturer meeting European standard EN71 and low lead standards in the United States. Their advanced technology, combined with a dedicated team of professionals, ensures that customer demands are consistently met. Star Lapel Pin's expansive manufacturing site spans over 64,000 square meters and employs 1000 skilled workers, emphasizing timely delivery and customer satisfaction.

Die Cast Pins

Cut Out Pins

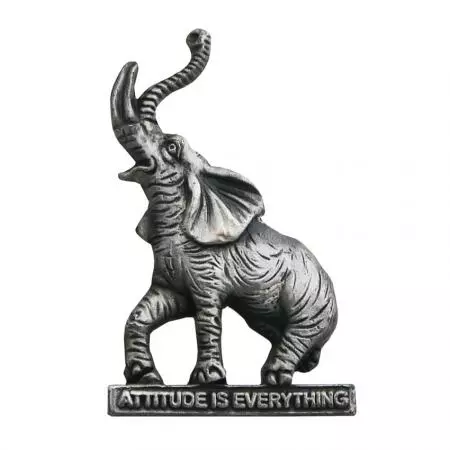

Die-cast pins are mostly used to design many inner cut holes and 3D logo need to stand out very much from the lapel pins. Because the material of zinc alloy is highly ductile, if the design is 3D or complicated, we strongly recommend using die casting material. For example, if the badge design size is more than 2", the thickness of the die casting material must be 3-4 MM or more, but the zinc alloy can be customized according to the design, and the thickness can be only 2 MM. If you need a thinner and lighter material, we recommend die casting pins.

Product Feature

The die casting pins are made of zinc alloy, pewter or tin material. The process is the molten metal is poured into the molds and created by spin casting. If your lapel pin design is many cut out style letters or designs with different layers dimension, the die casting pin is best choice. The die cast pins not only for no coloring design, it also can make the design color fills in however soft enamel or imitation hard enamel.

Pioneering Craftsmanship in Custom Metal Products

Step into the realm of excellence with Star Lapel Pin Co., LTD, a distinguished professional manufacturer boasting years of expertise in crafting custom metal craft products. Our versatile journey has led us to master various production processes, including stamping brass/iron/aluminum, spin casting, and die casting zinc alloy, enriched with hard enamel, imitation hard enamel, soft enamel infills, and printing techniques – a plethora of options for our valued customers.

What sets us apart is our holistic approach. Every aspect of production, from stamping/casting, meticulous polishing, vibrant plating, vivid coloring, stringent quality inspections, to meticulous packaging, occurs within our in-house facilities. Moreover, our own electroplating facility proudly holds annual accreditation from Chinese authorities as an environmentally responsible manufacturer.

Elevate your expectations with Star Lapel Pin Co., LTD – a beacon of distinction in crafting custom metal masterpieces.

The procedure of zinc alloy die casting

If the design requires areas with cut-outs or the design requires more than a simple 2-stage embossing process, we can produce virtually any pin design using die casting, especially if you're looking for complex shapes. They work especially well for statues, animals and religious icons where a 3D look is required.

Specification

- Material: Zinc alloy, Pewter, Tin

- Process: Hard enamel, Imitation hard enamel, soft enamel, stamped or molded without coloring.

- Plating Process: Gold, Silver, Bronze, Nickel, Copper, Rhodium, Chrome, Black nickel, Dyeing black, Antique Gold, Antique Silver, Antique Copper, Satin Gold, Satin silver, dye colors, dual plating color

- Size: Custom made. According to customer's requirements.

- Shape: Custom made. According to customer's requirements.

Order Information

- MOQ: 100 PCS per design

- Package: OPP Bag

- Payment: T/T / PayPal / Credit Card

- Delivery: Need to confirm again when customer approved the artwork / samples.

- Lead Time: 15-20 days. lead time is negotiable.

- Related ProductsFAQ

Lapel Pin Backs/ Pin Attachments

As a professional metal pin badge manufacturer, Star Lapel Pin offers multiple lapel pin back...

DetailsPhoto Etched Pins

The production process of photo etched pin is drawing, making etching film, printing the image...

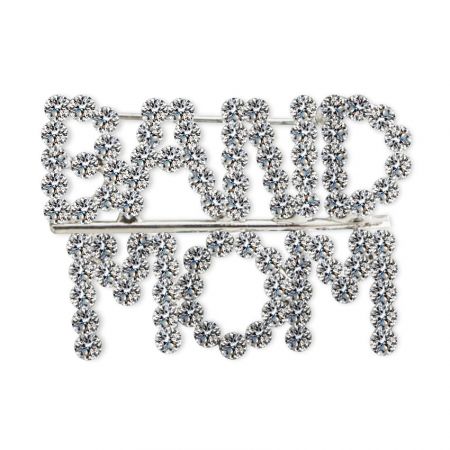

DetailsRhinestone Lapel Pin

The rhinestone lapel pin process by die casting (zinc alloy) material and the attachment is brooch...

Details

Die Cast Pins | Soft PVC Promotional Products manufacturer | Star Lapel Pin

Located in Taiwan since 1984, Star Lapel Pin Co., Ltd. has been a manufacturer of custom promotional products. Their main promotional gifts and souvenirs include, Die Cast Pins, custom lapel pins and medals, challenge coins, metal souvenirs, personalized leather souvenirs, custom metal promotional products, corporate giveaways and soft PVC and silicone items, which offers high-quality items tailored to B2B buyers globally.

They comply with the European EN71 standard and low lead standards in the U.S. With over 36 years in the metal industry, they have continuously updated their machinery and equipment. Their manufacturing facility covers over 64,000 square meters and employs 1000 experienced workers. They have been providing high quality promotional gifts since 1984 and ensure customer satisfaction with every order.

Star Lapel Pin has been offering customers high-quality promotional gifts since 1984, both with advanced technology and 40 years of experience, Star Lapel Pin ensures each customer's demands are met.

Have any Question?

You are welcome to contact us via email directly:

service@starlapelpin.com